OPTICAL CONTINUITY TESTER

PRODUCT OVERVIEW

OPTICAL CONTINUITY TESTER

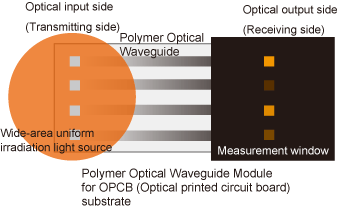

MEASUREMENT METHOD OF OPTICAL CONTINUITY TESTER

FEATURE

- Optical continuity tester with one-shot irradiation system for measurement light as mass production inspection compliant.

- Newly developed one-shot irradiation system for measurement light and high NA detection optical system should realize high speed and high accuracy test.

- Extraction, processing and automatic measurement only for propagation optical intensity signal from optical waveguide with proprietary software.

- In combination with high precision motorized stage system, it is possible to execute additional function such as defocusing mode measurement, core shape / pitch / position measurement, full-automatic measurement system and so on.

APPLICATION

- High-speed optical continuity test for polymer optical waveguide for OPCB substrate at mass production.

- Pass/Fail judgement of continuity condition by relative loss measurement and comparison with reference.

- Defocus measurement

- Area intensity measurement at virtual position of detector.

- Core pitch measurement

- Core position measurement

- Inclination measurement of 45° built-in mirror in polymer waveguide.

SYSTEM COMPONENT SELECTION

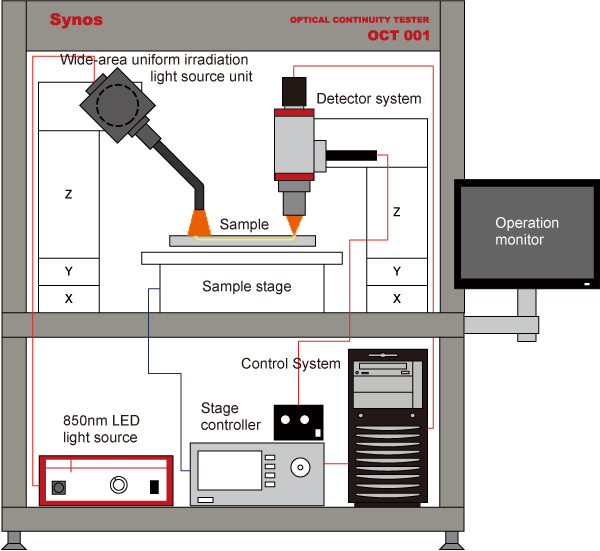

SYSTEM CONFIGURATION DIAGRAM

COMPONENT SELECTION

- Wide area uniform light irradiation unit

- Output N.A. : 0.57

- Irradiation size : approx.φ4mm (@5mm gap)

- Uniformity in irradiation surface : ±2%

- Light source : 850nmLED

- Center wavelength of light source : 850nmLED (FWHM:±40nm)

- Maximum output power : approx. 15mW

- Output light stability : ±1%

- Dedicated large N.A. measurement optics

- Detection N.A. : 0.4

- Optical magnification : 5× (20× objective lens is used)

- Field of view : 1.28mm×0.96mm

- Detector

- 400~1100nm: High Resolution CMOS Detector ISA071

- Total pixels : 2048×1536 pixels (approx. 3.2 megapixels)

- Pixels pitch : 3.45×3.45μm

- Sensor size : 1/1.8 inch

- Gradation : 12bit

- Stage system

- Stage system for input side light irradiation unit

- Stage system for output side measurement optics

- System platform, bracket, etc,

- Sample stage

- Sample stage

- Sample holder

- System Control

- Computer for data processing and system control

- Monitor for operation

- Control and analysis software for Optical Continuity Tester

- Stage control system

- System main control unit

- System power supply unit

- Safety equipment etc.

- Incidental facilities

- Shield box

- Vibration isolated stage

- *Configuration written above is a standard example, and we can deliver any configuration according to the applications.